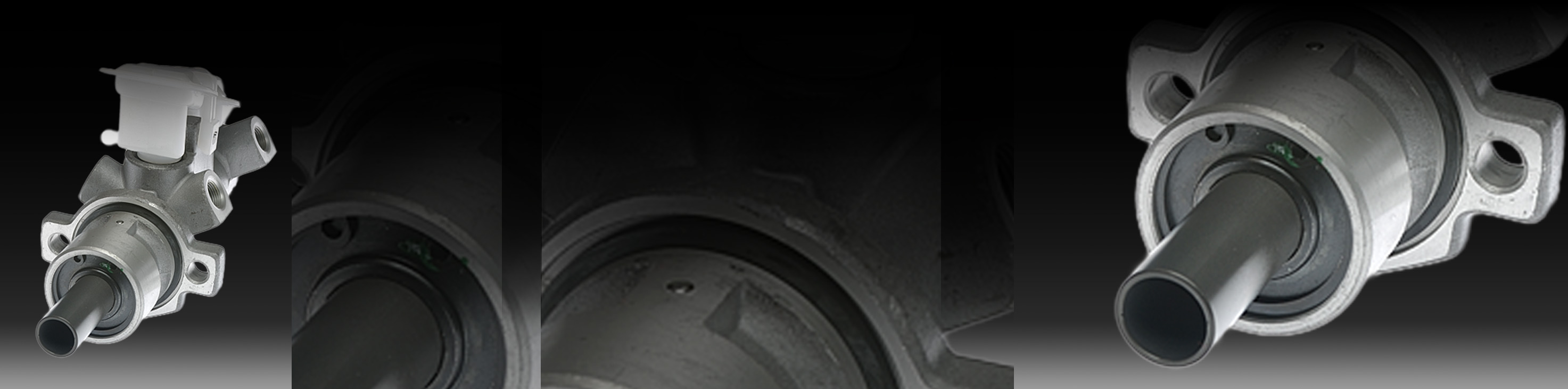

All units are manufactured to meet or exceed OE specifications, with component enhancements including OE grade EPDM seals, O-rings, negative-ground switch sensor fittings and crack-resistant vinyl based reservoirs. Each unit is precision machined and 100% pressure tested before it leaves our factory. MPA Master Cylinders are supported by a free tech support hotline, staffed by ASE certified master technicians with access to extensive vehicle-specific repair data.

Quality Enhancements

100% New OE-Grade EPDM Seals and O-Rings

-

Resistance to internal and external temperature fluctuations. Our seals maintain consistent brake force pressures necessary to safely stop the vehicle.

New Negative-Ground Sensor Fittings

-

Eliminates the transfer of potentially faulty sensors, leading to possible misdiagnosis and future service requirements.

Premium Grade Reservoirs

-

Resistant to cracking during sudden fluctuations in operating temperatures.

Precision Machined Bores and Pistons

-

Micro-finished surfaces provide the foundation for smooth, consistent and trouble free braking power when you need it most.

100% Computerized Multi-Stage Testing

- Tested under load on MPA-designed and built computerized testers. Our quality standards ensure performance right out of the box.